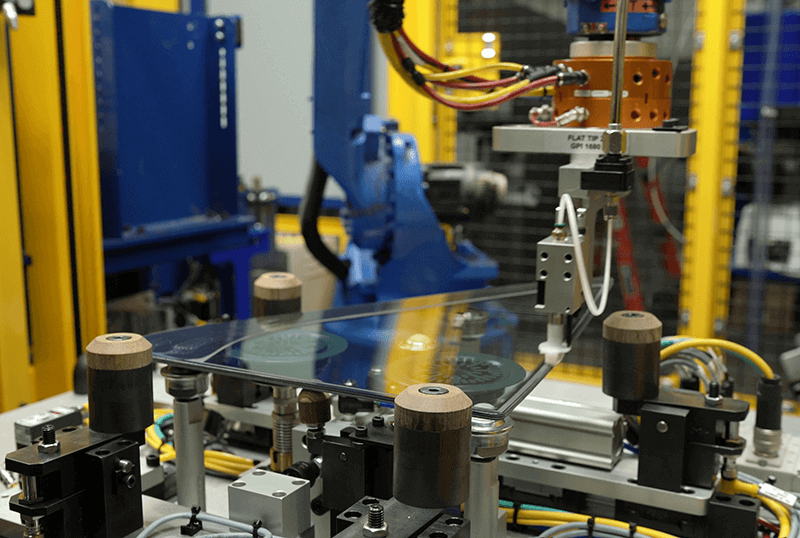

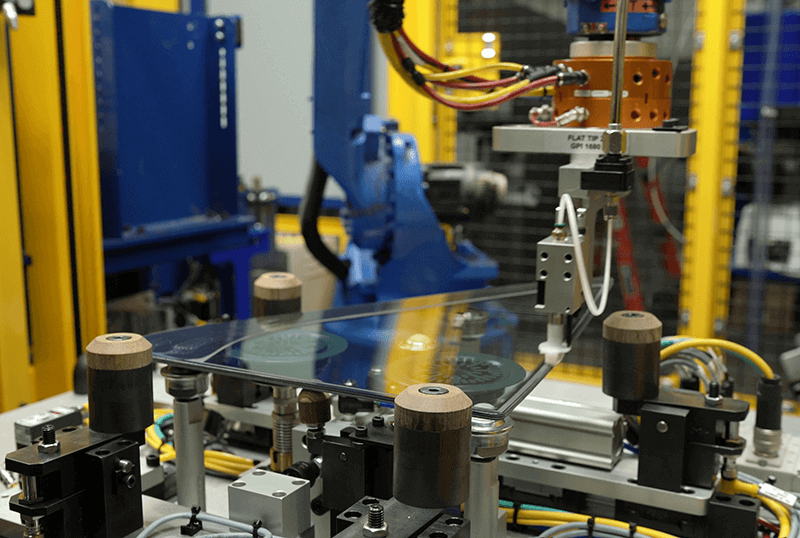

Robotic Adhesive Application

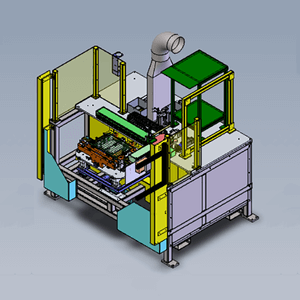

Our robotic adhesive application system will apply precise, measured beads of adhesive to your surface, bond all of your components in place, and so much more.

You can count on our expert engineering and manufacturing teams to create a seemless integration with your current equipment.

Robotic Adhesive Application

Our robotic adhesive application system will apply precise, measured beads of adhesive to your surface, bond all of your components in place, and so much more..

You can count on our expert engineering and manufacturing teams to create a seemless integration with your current equipment.

Save labor costs and boost profitability with a turnkey robotic adhesive application system.

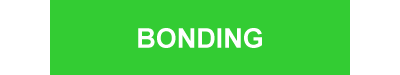

Using the latest robotic technology paired with a carefully designed and calibrated adhesive dispensing system, Hil-Man will deliver a turnkey robotic adhesive application cell that not only provides more control over your bonding process, but also saves costs and increases profits.

The best adhesive dispensing systems are properly designed and calibrated to lower the cost of production and increase profits. This requires seasoned engineering and automation experts who know manufacturing. Hil-Man Automation specializes in turnkey robotic adhesive application solutions that put our customers in control of their bonding process.

Integrate additional tasks to get more done in less time with less expense.

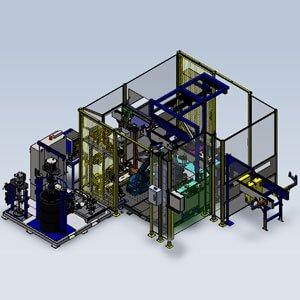

Not only will your new adhesive application system apply precise beads of urethane and hot melt to your automotive glass–it can first check the barcode, clean the surface, and apply all necessary primers before bonding all your components and seals in place, and transferring the assembled glass to a conveyor.

Integrate additional tasks to get more done in less time with less expense.

Not only will your new adhesive application system apply precise beads of urethane and hot melt to your automotive glass–it can first check the barcode, clean the surface, and apply all necessary primers before bonding all your components and seals in place, and transferring the assembled glass to a conveyor.

A turnkey robotic adhesive application cell you can count on.

Hil-Man Automation recently launched Precision Dispense Technologies to supply our customers with the quality meter-mix and dispensing products that make up a solid robotic adhesive application system.

Trust the expert team at Hil-Man Automation and committed support staff to deliver your turnkey robotic adhesive application system. Designed to meet your goals and built strong enough to withstand daily use and abuse, Hil-Man’s automated adhesive application cells stand out among the rest.

Want to see our robotic adhesive application capabilities in action?

Here are a few examples–click the drawings below for photos and descriptions of each project.

How can we help you?

We have the expertise, experience and capacity to deliver your primer application equipment–on time.

How can we help you?

We have the expertise, experience and capacity to deliver your primer application equipment–on time.

Not sure what you need yet?

Our engineering sales and design team can talk you through every option and specification for your primer application equipment. Hil-Man experts are available to visit your facility to assess your current production line to ensure a seamless integration.

We also offer full servicing, refurbishing, and upgrading on existing systems to help you improve speed and accuracy with minimal investment.